8 January, 2025

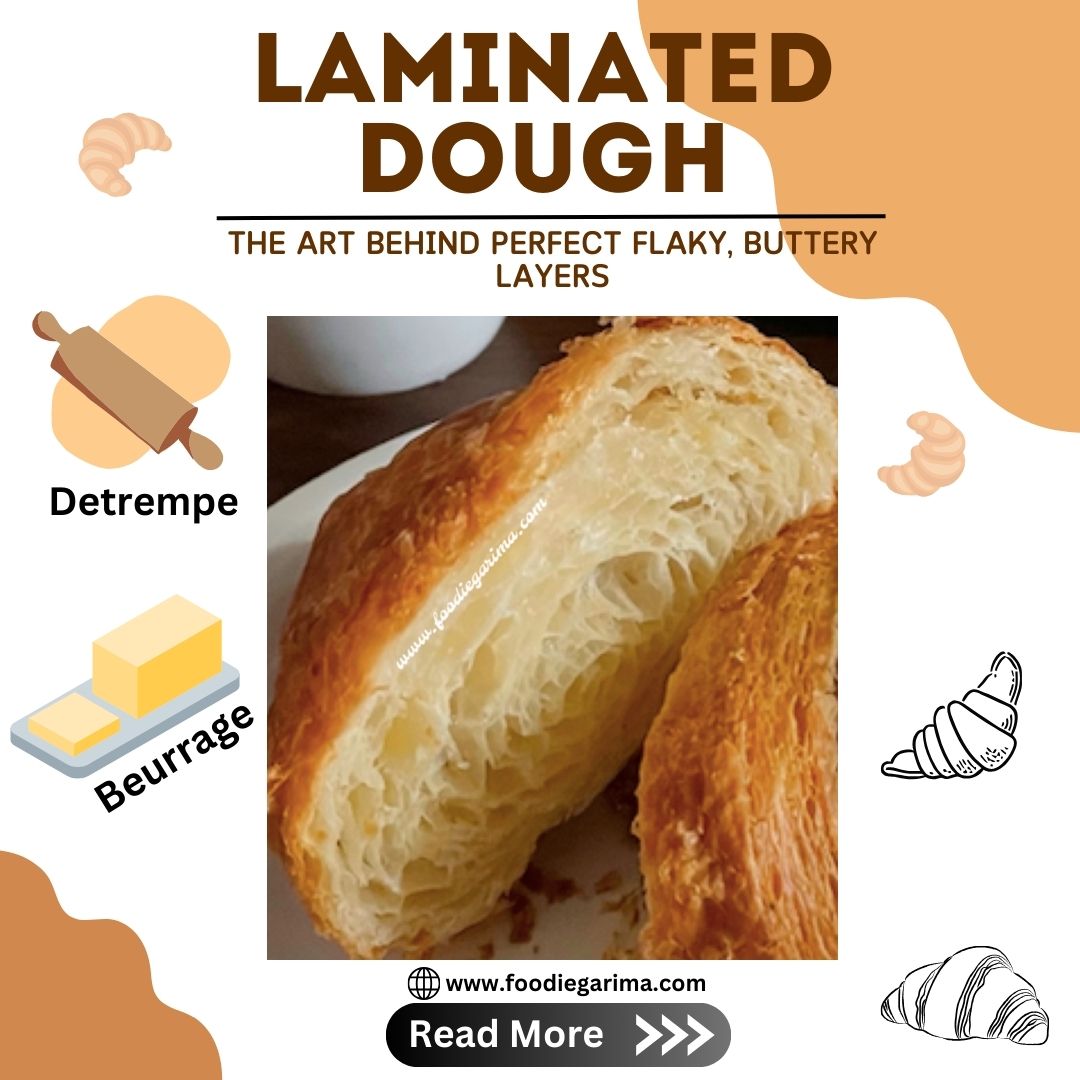

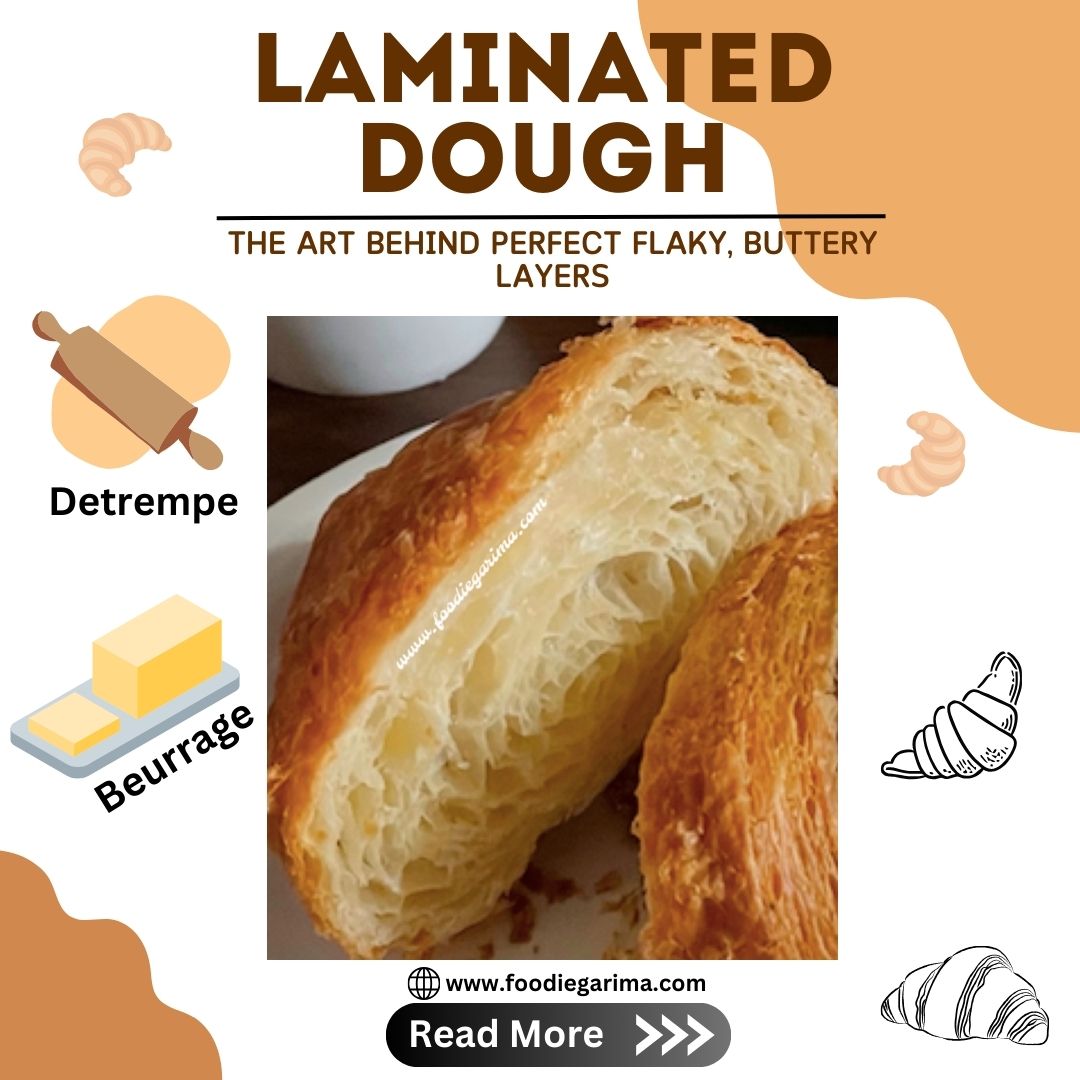

Laminated Dough | The Art Behind Perfect Flaky, Buttery Layers

Laminated Dough | The Art Behind Perfect Flaky, Buttery Layers

Ever wondered what gives a Croissant its buttery layers or a Puff Pastry its incredible flakiness?

The secret lies in Laminated Dough—a marvel of culinary engineering that combines simplicity and sophistication. Laminated Dough is not just a baking technique; it’s an art form that transforms simple ingredients into something extraordinary.

Understanding Laminated Dough

What is Laminated Dough?

“Laminated Dough” involves a technique where “layers of Butter” are folded into “Dough” multiple times, resulting in many thin, delicate layers. The Dough’s structure is designed in a way that, when baked, it puffs up beautifully due to steam being trapped between the layers of Dough and Butter. The process of layering is key to creating that signature flakiness and buttery flavor.

It’s the foundation for many beloved Pastries like Croissants, Puff Pastry, and Danish Pastries.

A Brief History

The origins of Laminated Dough are often traced back to France, but some argue its roots are even older, linked to Middle Eastern and Mediterranean pastries. Regardless, it’s now a cornerstone of European patisserie.

Types of Laminated Dough

Croissant Dough

Croissant dough includes Yeast, making it slightly bread-like with a tender, flaky texture. Ideal for sweet and savory fillings.

Danish Dough

Sweeter and richer than Croissant dough, Danish dough is often used for pastries filled with fruits, creams, and jams.

Puff Pastry Dough

Unlike Croissant and Danish dough, Puff Pastry dough has no Yeast. It relies entirely on the lamination process for its rise, resulting in ultra-crisp, multi-layered creations.

Why Lamination Matters

The goal is to create multiple layers that puff up during baking, resulting in a flaky, tender texture.

The magic of Laminated Dough lies in its ability to combine buttery richness with an airy, delicate texture. It’s the reason Croissants and Puff Pastries melt in your mouth yet remain satisfyingly crisp.

To understand this process fully, we need to delve into the two primary components of Laminated Dough: Beurrage and Detrempe.

Beurrage and Detrempe: The Foundation of Laminated Dough

Beurrage: The Butter Layer

- Beurrage refers to the block of butter that is incorporated into the dough.

- The butter needs to be cold and pliable, so it can be rolled out without breaking or melting into the dough. A key element in creating laminated dough is maintaining the right consistency of the butter, as it must be soft enough to roll but firm enough to hold its shape and create those signature layers.

- The butter is folded into the dough during the lamination process to form the layers.

- High-fat European-style butter (dry butter) works best due to its pliability and flavor.

Dry butter (butter with a higher fat content and lower water content) is important for making laminated dough, especially if you’re aiming for professional-quality pastries like croissants, puff pastry, or Danish pastries. Here’s why dry butter is preferred:

What is Dry Butter?

Dry butter, often referred to as European-style butter, contains about 82–85% fat and less water (compared to standard butter, which has about 80% fat). This higher fat content makes it more pliable and less prone to melting, which is crucial for lamination.

Why is Dry Butter Important for Laminated Dough?

- Better Layer Formation:

- Less water means the butter is less likely to seep into the dough layers during lamination, helping maintain distinct, separate layers of dough and butter.

- Consistency and Pliability:

- Dry butter remains pliable at cooler temperatures, making it easier to roll out and fold without cracking or breaking.

- Regular butter can become brittle when cold or melt too quickly when warm, which can compromise the lamination process.

- Steam Production:

- During baking, laminated dough relies on steam from the butter to puff up the layers. Since dry butter has less water, it produces just the right amount of steam without overhydrating the dough.

- Flakier Texture and Richer Flavor:

- The higher fat content contributes to a richer, more buttery flavor and creates a flakier, more delicate texture in the final product.

What If You Don’t Have Dry Butter?

If dry butter isn’t available, here are some tips to compensate:

- Chill Regular Butter Well: Use regular unsalted butter but make sure it’s very cold before incorporating it into the dough.

- Adjust Temperature: Work in a cool environment and chill the dough frequently to prevent the butter from melting into the dough.

- Homemade Dry Butter Substitute: Mix standard unsalted butter with a small amount of flour to mimic dry butter’s consistency. Flour absorbs the moisture and makes the butter dry. This can help stabilize the butter for lamination.

While regular butter can work, dry butter is highly recommended for achieving the signature flaky texture and buttery flavor of laminated dough. It’s a small upgrade that makes a significant difference, especially for complex pastries.

Shaping the Butter:

- Place the butter between two sheets of parchment paper.

- Use a rolling pin to flatten the butter into a rectangular block, typically about 1/4 to 1/2 inch thick.

- Ensure the butter block’s size matches the dimensions of the detrempe after rolling.

- Chill the butter block in the refrigerator until firm but pliable (around 15–20 minutes).

Detrempe: The Base Dough

- The detrempe is the base dough made from Flour, Water, Salt, and a small amount of Fat, usually Butter or Oil. It serves as the foundation that will hold the butter (beurrage) and be transformed into flaky layers.

- The dough (detrempe) must be mixed and rested to develop gluten but not overworked to ensure that the dough is tender rather than tough.

1. Ingredients:

- Flour: The foundation of Laminated Dough requires high-protein flour for gluten development, which ensures elasticity and structure. Bread flour or a mix of bread and all-purpose flour is ideal for its gluten-forming proteins.

- Water: Water hydrates the flour, helping to develop gluten and form the dough.

- Salt: Adds flavor and strengthens the gluten structure.

- Fat: A small amount of butter or oil is often added to the dough to increase pliability.

Using ice-cold water is highly recommended when preparing the detrempe for laminated dough. Here’s why:

Why Ice-Cold Water is Essential

- Temperature Control:

- Laminated dough requires the butter (beurrage) and dough (detrempe) to stay cold during the process. Ice-cold water helps keep the dough cool while mixing, preventing the butter from melting prematurely.

- Gluten Development:

- Cold water slows down gluten development, making the dough easier to roll out without becoming too elastic or tough. Overdeveloped gluten can cause shrinkage during baking.

- Consistency:

- Cold water helps maintain the dough’s pliability and prevents it from becoming sticky, which is important for achieving smooth layers during lamination.

How to Use Ice-Cold Water

- Fill a small bowl or measuring cup with cold water and a few ice cubes.

- Allow the water to sit for a few minutes so it becomes thoroughly chilled.

- Measure the required amount of water for the recipe from this ice-cold water.

Using ice-cold water is a simple step that ensures the dough remains cool and manageable throughout the process, helping you achieve the perfect flaky layers in your laminated dough.

2. Preparing Detrempe:

- Mixing:

- Combine flour and salt in a mixing bowl.

- Add the butter (if using) and rub it into the flour lightly to distribute evenly.

- Gradually add cold water while mixing until the dough comes together. Avoid overmixing.

- Kneading:

- Lightly knead the dough on a floured surface for 2–3 minutes until it forms a cohesive, smooth ball. Do not over-knead, as this can overdevelop the gluten, making the dough harder to roll.

- Resting:

- Wrap the detrempe in plastic wrap and refrigerate for at least 30 minutes. Resting relaxes the gluten, making the dough easier to work with during lamination.

The Laminating Process

The basic technique of lamination involves a series of folds and turns to create the thin layers of dough and butter. Here’s a breakdown of the typical process:

- Preparation: The detrempe (dough) and beurrage (butter) are prepared separately. The beurrage is shaped into a thin, square block, while the detrempe is rolled into a rectangle. It’s important that both the dough and butter are at the right temperature, typically chilled, to avoid the butter melting into the dough prematurely.

- Enclosing the Beurrage: The beurrage is placed in the center of the detrempe, and the edges of the dough are folded over the butter to encase it fully. This is known as the “envelope fold.”

- Rolling and Folding: The dough is then rolled out into a long rectangle, and the edges are folded into thirds, similar to folding a letter. This is called a “single fold.” After each fold, the dough must rest in the refrigerator to chill. The chilling process helps maintain the integrity of the butter and allows the dough to relax, making it easier to roll out.

- Multiple Turns: The dough undergoes several “turns” (folds and roll-outs), typically three to six, depending on the desired number of layers. Each fold increases the number of layers and the dough’s flakiness. The more turns, the more layers and a lighter, flakier texture.

- Final Resting: After the final turn, the dough is rested again to allow the layers to set before being shaped and baked. This resting period is crucial for the dough’s texture.

By combining the beurrage and detrempe with care and precision, you set the foundation for creating laminated dough with perfect layers and textures. Adjust the ratios slightly based on the recipe or the specific pastry you’re making, but the principles remain the same: balance, consistency, and patience.

Steam Magic

When laminated dough is baked, the water in the butter and dough turns to steam. The steam gets trapped between the layers, causing them to puff up, which gives laminated dough its signature light and flaky texture.

Other Key Elements of Laminated Dough

- Temperature Control: One of the most important factors in working with laminated dough is temperature control. If the dough becomes too warm, the butter can melt into the dough, ruining the lamination process. Therefore, it’s important to work in a cool environment and chill the dough regularly.

- Quality of Butter: The quality of the butter is essential for the final flavor and texture. High-fat butter with a low moisture content works best as it creates more layers and a richer taste.

- Flour Choice: For laminated dough, bread flour or pastry flour is often preferred because it has a higher protein content that helps develop gluten, giving the dough structure and the ability to support the layers.

- Temperature Match: The butter block (beurrage) and the dough (detrempe) should be at the same consistency. If one is too firm or soft compared to the other, the layers can tear or merge, compromising lamination.

Common Mistakes and How to Avoid Them

Overworking the Dough

Overworking the dough can lose its flakiness. Work quickly and chill often to keep the butter intact.

Butter Temperature

Butter that’s too soft will blend into the dough. Too hard, and it’ll break apart. Aim for a pliable yet firm consistency.

Popular Pastries Made from Laminated Dough

- Croissants: The quintessential laminated pastry, croissants are made from a dough that’s been laminated with butter, resulting in a light, flaky, and buttery texture.

- Puff Pastry: Puff pastry, another classic laminated dough, consists of multiple layers of dough and butter that puff up dramatically when baked. It’s used in a variety of sweet and savory dishes, from tarts to turnovers.

- Danish Pastries: These pastries combine laminated dough with various fillings, such as cream cheese, fruit, or almond paste, offering a rich, indulgent breakfast or dessert treat.

Laminated dough is an essential technique in pastry making that transforms humble ingredients into a luxurious, flaky texture. The combination of detrempe (dough) and beurrage (butter) through a process of folding and resting creates pastries with exquisite layers, buttery flavor, and an airy, light finish. Whether you’re making croissants, puff pastry, or Danish pastries, understanding the principles of laminated dough will elevate your baking to new heights. With patience, precision, and the right ingredients, anyone can master this art and enjoy the delicious fruits of their labor.